|

Tech Talks Modifying your Factory Sending Unit

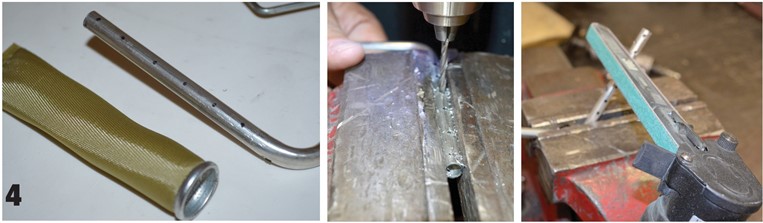

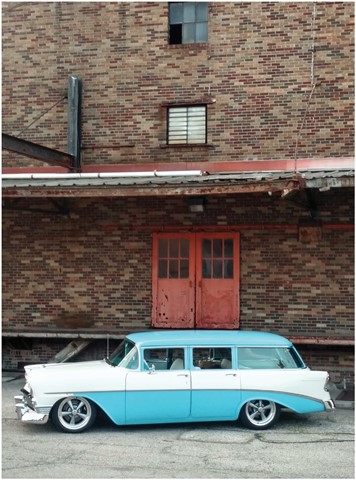

Many of the cars being built today are being built with electronic fuel injection and because of that those cars have to run electric fuel pumps. A manual fuel pump generally pumps at between 5-6Ibs of pressure and most EFI applications need 55Ibs or more pressure. The aftermarket has responded nicely to this trend and many manufactures have designed fuel injection tanks that have the electric pumps built in to them. The Danchuk # 14948 (Photo#1) features a factory spec sending unit and internal fuel pump that is rated at 85-115 PSI at 50-60 gph. It also features a return line provision because most new fuel injection systems require a return fuel line and an external regulator to keep the fuel pressure constant at the intake. I highly recommend that if you are making the jump to an LS engine or anything with electronic fuel injection that you spend some time looking at the fuel needs of your set up and don't skimp on the fuel tank, pump and filters. If an in-tank system like the Danchuk #14948 I would recommend using it. Unfortunately no one makes a wagon tank with an in tank pump so for our project Wagoonie we chose to use a new Golden Star GT13-553 (Photo #2) wagon tank and modify it to work with our EFI engine. First we added a bung for a return line to be hooked to. It is the next step that hurt us! Most aftermarket pump manufactures say right in their instructions that the "sock" that is on the pick-up tube must be removed prior to installing the sending unit, so we did just that. The reasoning is that due to the extreme pull that an electric pump has compared to a mechanical pump the sock can get sucked into the pick-up tube and restrict fuel flow. Most instructions go onto say that. "debris in the tank will be filter by the pre-filter" that is recommended to be put in-line in front of the external electric fuel pump. Seems right, right? Well, I can assure you some debris can still be picked up and restrict fuel flow. Our Wagoonie traveled nearly 3,000 miles since it first hit the road problem free until at the worst time possible it quit running. Travelling down a freeway in heavy traffic the car stopped. Once home I began to diagnose the issue. First off, the pump was working so I knew that wasn't the issue. Next I checked for ignition, we had plenty of spark so obvious to me was the next check which was for fuel pressure. After putting a fuel pressure gauge on the fuel rail fitting and cranking the car it was discovered that I only had about 5Ibs of pressure at the manifold. So since the pump was working and there was still no pressure I looked to the fuel filter only to find it clean as a whistle. At this point in the diagnosis it was clear that there was an unexplained obstruction in the feed line from the tank. What was found when pulling the sending unit was alarming. A piece of RTV silicone had gotten lodged in the pick-up tube (Photo #3). How did it get there? Only guess is that when the sending unit was put on I normally put a small bead of RTV around the unit where the screw holes are to prevent fuel leaks. A small amount of RTV must have pushed through one of the holes and ended up in the tank. When RTV comes in contact with fuel it swells to about 4 times its normal size and once it got sucked into the pick-up tube it was only a matter of time before the fuel stream was restricted enough to cause an issue (Photo #4). Now that I have described the how the problem happened I will tell you the solution that I came up with. First off I dropped the tank and completely rinsed it out to be sure there were no other possible issues that could come back to bite me later on. Then I came up with a solution to the "sock" not being able to be used in this type of application. Since the pick-up tube has only one 3/8" opening it is clear to see why the sock could cause an issue, so I decided to drill a series of holes into the pick-up tube using a drill bit. I Swiss cheesed the tube with 20 3/16" holes. By doing this there is much more area for the fuel to enter the tube, thus eliminating any chance that it would collapse the sock and cause any issue. Also, there is no way with that many ways for fuel to enter the pick-up tube, and with the sock in place, that any contaminant in the tank could cause an issue. Once the sock was back in place I reinstalled the sending unit into the tank and I was back to cruising. Since the last four inches of the tube basically lays flat on the bottom of the tank below the float for the sending unit this Swiss cheese tube will not cause an issue with anything unless of course you run the car out of fuel. Please don't do that.  To order your Sending Unit, visit HERE. For a printable version of instructions, visit HERE. Brought to you by the American Tri-Five Association.  |